Describe 5 Tools Being Used in Sand Casting

2 Mould hardness test. The sand casting process involves the use of a furnace metal pattern and sand mold.

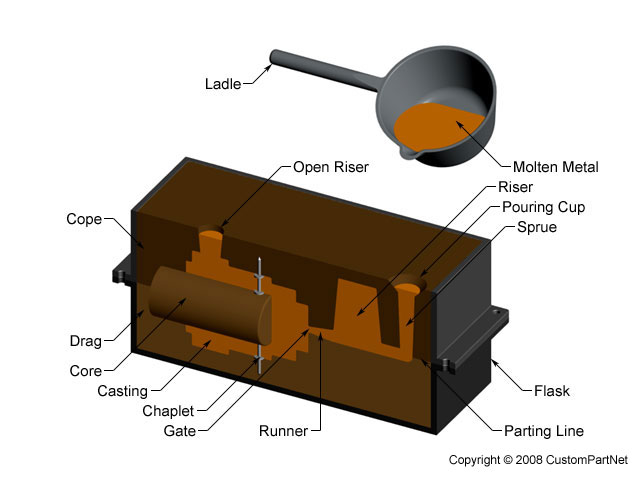

Sand Casting Process Defects Design

②Most of the used clay wet sand can be recycled and reused after proper sand treatment.

. Testing of Mould Core sand. Therefore manufacturing companies must create new molds to create metal products and components in specific sizes and shape. Cast Iron 2 Part Flask Mold for Delft Sand Casting Jewelry Making Tool.

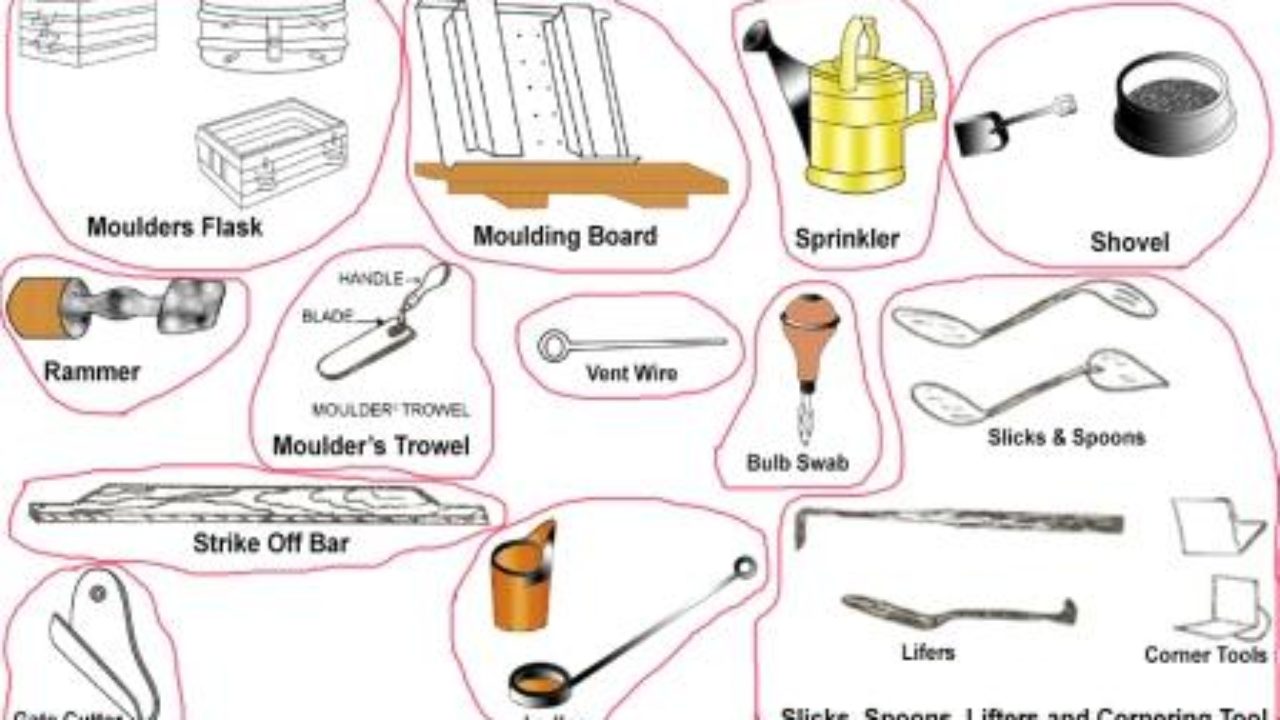

Green sand refers to the sand molds formed from wet sand and is sometimes referred to as clay. Different types of Casting tools and equipment Hand riddle. 8 Compression shear test.

④ The mixed molding sand can be used for a long time. A similar idea is used in casting very large gear rings etc. The six main steps in this process are.

Step 1 Place Mold Pattern in Sand. So care should be taken while making delicate products. Sand casting also known as sand molded casting is a metal casting process characterized by using sand as the mold material.

Anyone who has formed castles at the beach knows sand can be used to make detailed shapes. They are used for moving or transferring the molding sand into the container molding box or flask. Process steps in sand casting - 1.

Heres what this guide will cover. The type of pattern that consists of two or more parts used to make round or irregular molds. The principal casting tools are hand tools containers and mechanical tools.

Sand castings are produced in specialized factories called foundries. Molds made of sand are. The advantages of clay green sand casting are.

Vintage Pattern Maker Foundry Sand Casting Floats Spoons Antique Tool. Patternmaking The first step in sand casting is patternmaking. Breaking the mold and getting the casting.

5 Sieve analysis. 1 Preparation of standard test specimen. Over 60 of all metal castings are produced via sand casting process.

A device used to measure high temperatures. The sand mold separates along a. Reference Module in Materials Science and Materials Engineering 2017.

The size and shape of the casting is directly influenced by the mold. Cooling the mold to the room temperature. ③The cycle of manufacturing the mold is short and the work efficiency is high.

3 Core hardness test. Pouring the molten metal in the mold cavity. A mixture of sand and binders.

Depending on the material being cast metal or sand molds can be used. Then we put patterns into the sand boxes then put green sand or resin sand into the boxes then make the. We need make wooden resin or metal patterns according to the drawings or samples.

However in a foundry dealing with the heat of molten metal many factors must be considered for. A ceramic or graphite container used to hold metal as it is melted. You must remove the pattern you have placed to create mould remove that.

Hand tools consist of the rammer shovel riddle vent wire lifter slick trowel mallet swab. They are used for separating sand and another object that serve as obstacles when molding. Ending Mar 29 at 600PM PDT 3d 23h.

Sand casting is a process that utilizes non-reusable sand molds to form metal castings. Use a crucible made of Clay Graphite or Silicone Carbide to withstand the temperature of molten metal. There are many advantages in technology and economy.

The metal is melted in the furnace and then ladled and poured into the cavity of the sand mold which is formed by the pattern. Other Expendable Mold Casting Shell Molding Vacuum Molding Expanded Polystyrene Process. ① Clay is rich in resources and cheap.

The molten metal solidifies in the cavity between the interior of the mold and the exterior of the core. The term sand casting can also refer to an object produced via the sand casting process. Advantages of sand casting.

Sand casting die casting vacuum molding investment casting IC centrifugal casting slush casting shell molding etc are a few commonly used processes. The downside is that the sand is a soft mold and can collapse or shift during casting. Sand casting means the production processes that need sand as the main molding material it also means the casting products made by these processes.

4 Moisture content test on foundry sand. For the same alloy its tensile strength can be increased by an average of 25 and its yield strength can be increased by an average of about 20 and its corrosion. Hot forming processes such as die-casting investment casting plaster casting and sand casting each provide their own unique manufacturing benefits.

In addition sand is used to make any cores that are contained in the mold. What tools are used in casting. Making a proper gating system in the mold.

On one hand casting is a deceptively simple manufacturing process. ② The most used clay wet sand can be recycled after proper sand treatment. Although casting is one of the oldest known manufacturing techniques modern advances in casting technology have led to a broad array of specialized casting methods.

Some examples of items manufactured in modern industry by sand casting process are cylinder heads valves engine blocks pump housings machine tool bases pulleys engine manifolds bearings gears bushings brush holders brackets lever arms electrical contact parts hardware machinery parts nuts landing gear. Sand Casting Mold Frame Cast Iron 2-Part Flask for Jewelry Metal Casting Tool. The first step of sand casting involves the placement of the mold pattern in sand.

① Clay is rich in resources and cheap. 6 Clay content test. ③ Short manufacturing cycle and high work efficiency.

Define the cavity inside a mold. Sand casting using green sand is quick and inexpensive since the sand can be reused. Fill with aluminum pieces.

The sand mold is in an uncured state as the metal is being poured. The mould cavit View the full answer. Incorporate the pattern and sand in a gating system.

There are the five basic steps to creating a sand casting. A machine used to mix sand for casting. ⑤ After the sand mold is compacted it can still be subjected to a small amount of.

The type of pattern that has only one part. 7 Permeability test. Pattern making and placing it the sand mold.

Metal to casting and sand casting comparison. You must place a pattern in sand to create a mould. 1 The mechanical properties of metal castings are higher than sand castings.

In this guide were breaking down six different areas of casting defects to help you pinpoint fix and avoid issues with your castings.

Hand Tools Used In Foundry Shop Engineers Gallery

Comments

Post a Comment